-

Contact Us

- Phone:13926939747

- Fax:+86 756 8679535

- Email:2850298518@qq.com

- Addr:NO.3 Pingxi Wu Road, Nanping Technology Park, Zhuhai City, Xiangzhou District, Guangdong Province, China

Successful Case | Lingke Ultrasonic Lace Machine

Auther: Date:2025/7/22

In the field of medical protection, the aseptic integrity and structural reliability of surgical gowns are directly related to the safety of doctors and patients. Traditional sewing techniques have inherent defects such as pinhole leakage and thread detachment, which not only reduce protective performance but also pose a risk of microbial infiltration. Faced with increasingly strict quality requirements in the medical device industry, how to achieve efficient, reliable, and pinhole free sealed connections has become a technical challenge that the surgical gown manufacturing industry urgently needs to overcome.

As a national high-tech enterprise, Lingke Ultrasonic is deeply involved in the field of polymer material welding. With industry-leading ultrasonic welding technology, it provides innovative solutions with high sealing, high strength, and high efficiency for the medical protection industry.

01 Customer Pain Points and Core Needs

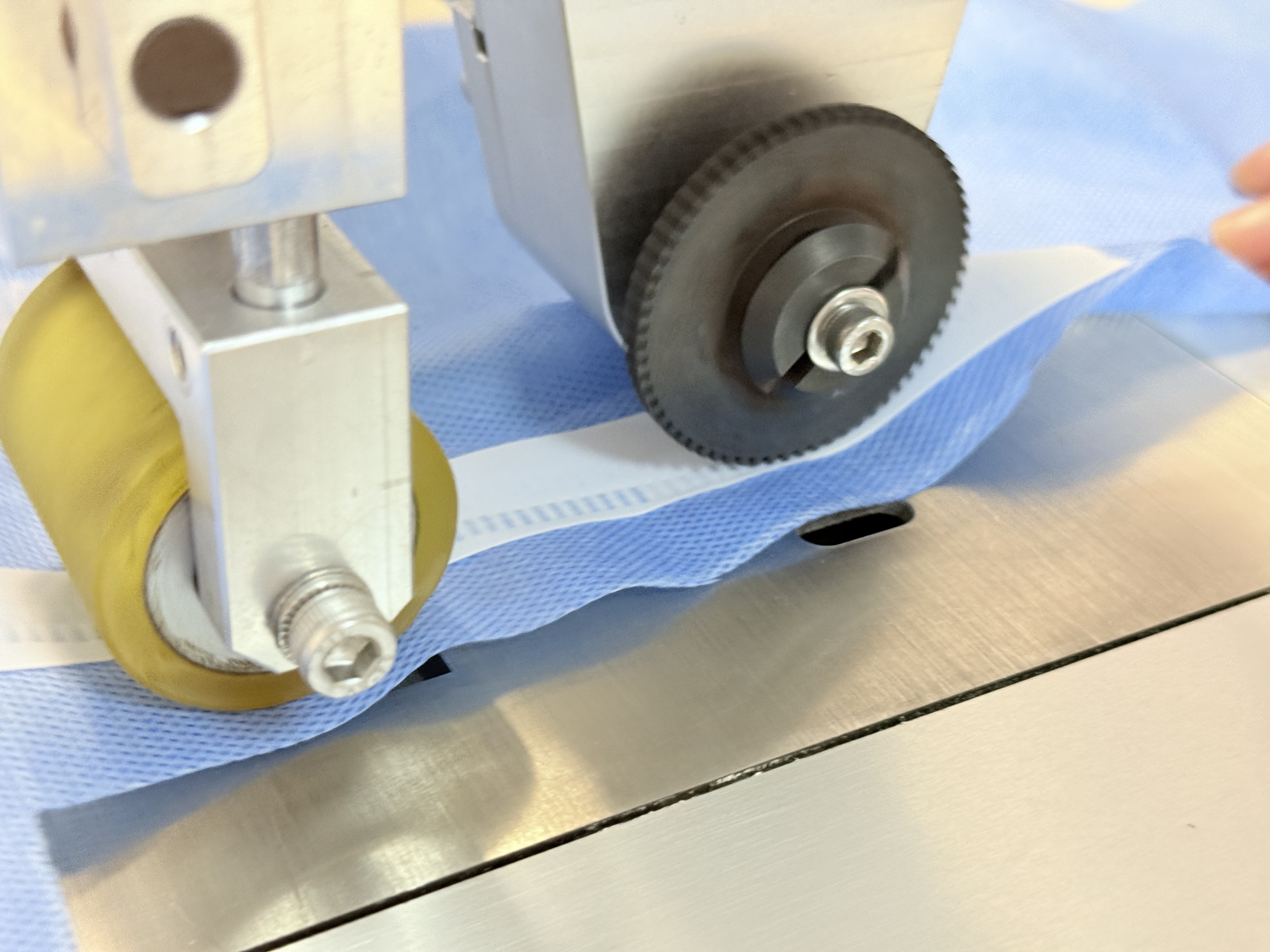

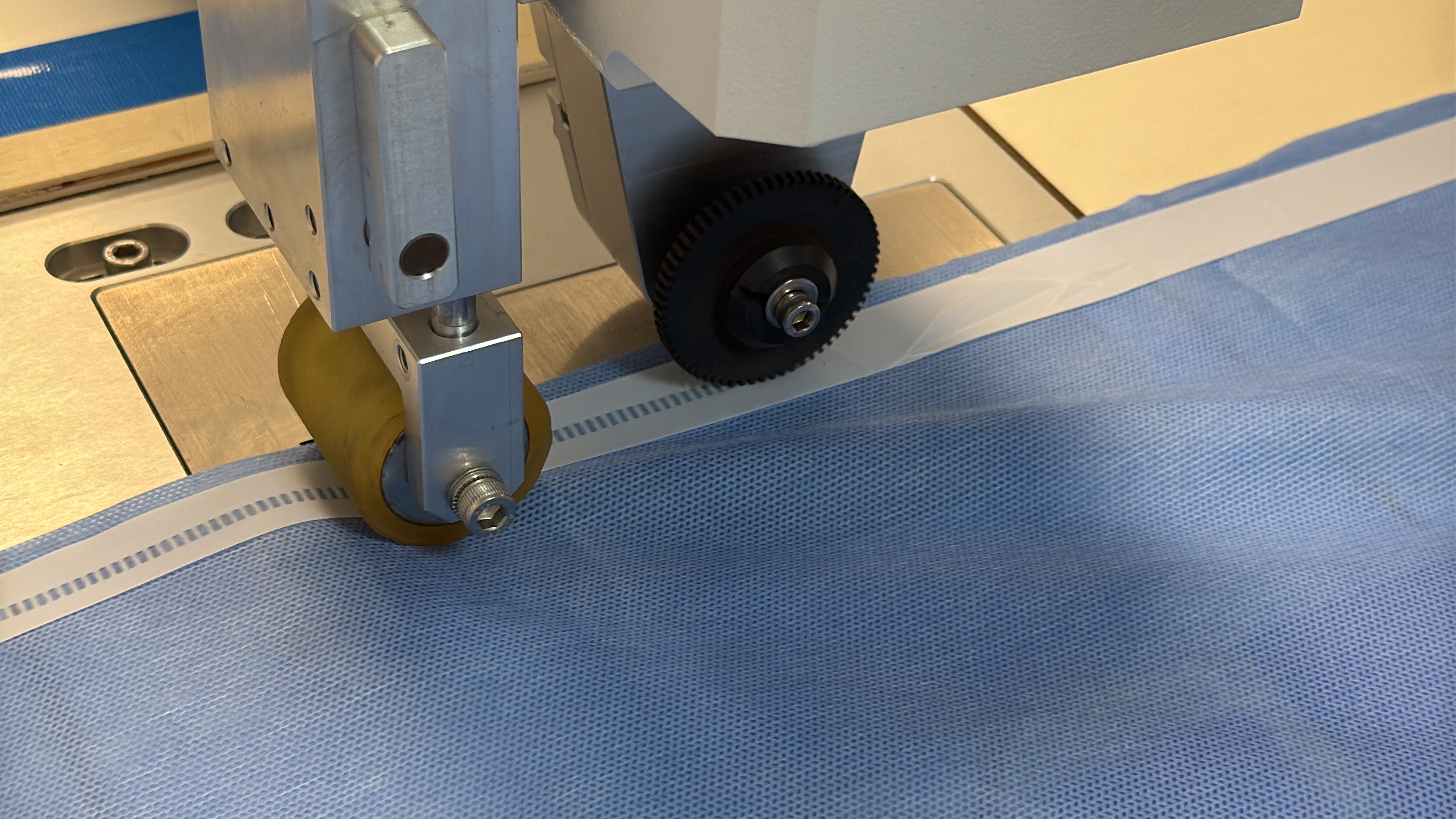

This case focuses on non-woven surgical gowns, with a multi-layer non-woven composite structure as the main body, combined with nylon Velcro hook materials.

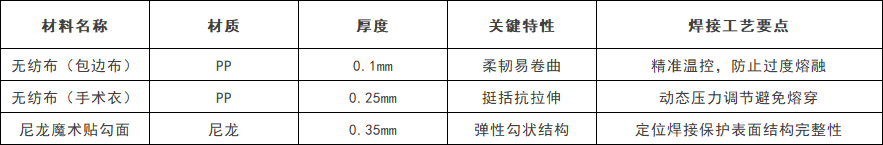

Core product: Polypropylene (PP) non-woven surgical gown (main body thickness 0.25mm), paired with edging cloth (PP, 0.1mm) and nylon Velcro hook surface (0.35mm).

Key process requirements:

Edge welding: The edge cloth covers the surgical gown, and the weld seam should be uniform and firm to prevent welding through or melting.

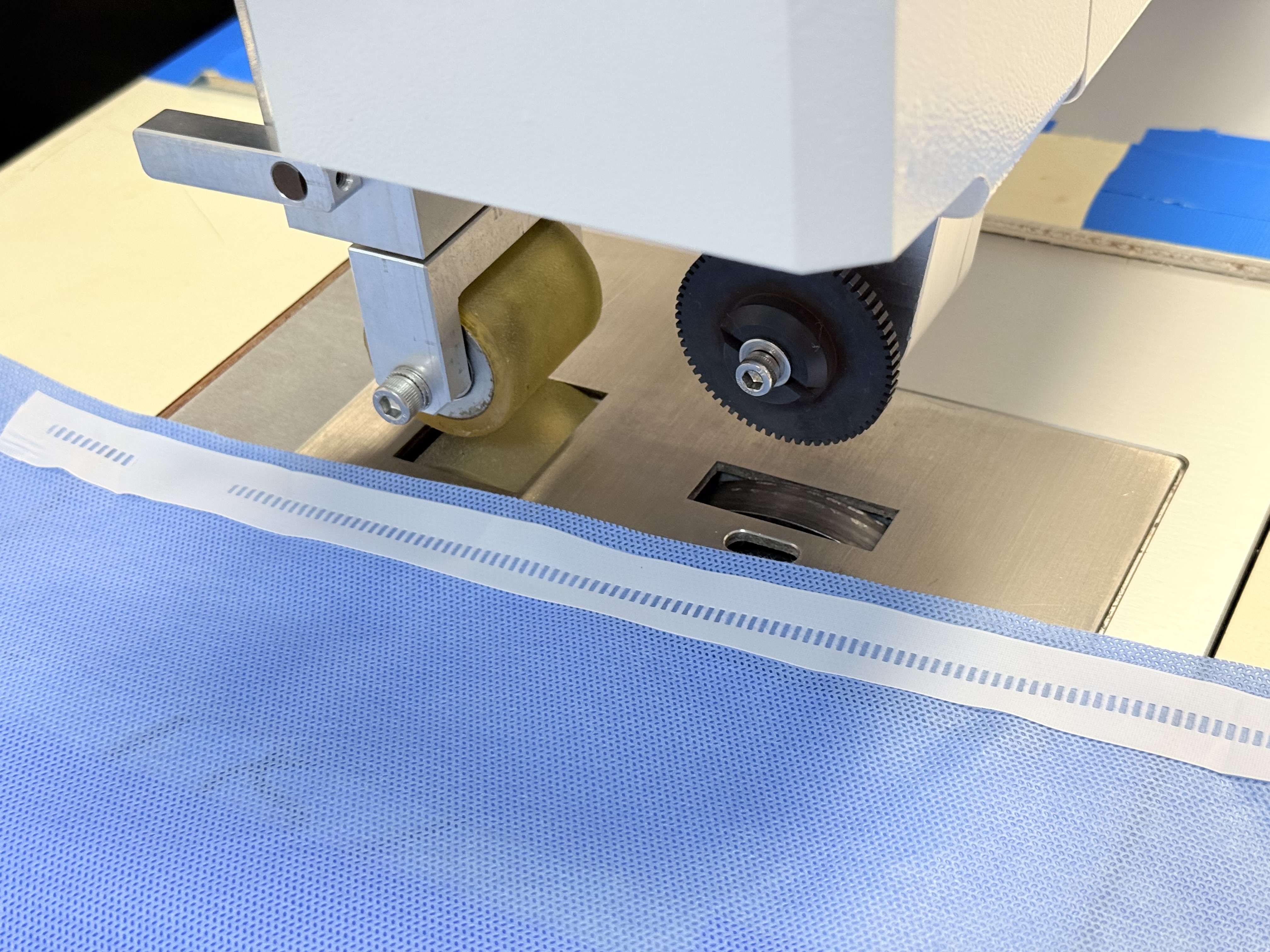

Velcro fixation: The nylon hook surface is welded to the surgical gown, ensuring a stable connection without damaging the elastic hook surface structure.

Quality standards: The entire process complies with medical device production standards, ensuring product sterility barrier and durability.

02 Comprehensive Analysis of Pain Points in Traditional Craftsmanship

Our cooperative clients have been deeply trapped in the sewing process dilemma:

Low production efficiency: manual threading and changing of wires are time-consuming and laborious, and production capacity is limited

High operating costs: continuous consumption of consumables such as sutures, and rising maintenance costs

Frequent quality control issues: loose seams, fuzzy edges, and other quality problems

Obvious appearance defects: visible pinholes, uneven stitching affecting product grade

Hidden protective hazards: Microscopic pores pose a risk of bacterial infiltration that is difficult to eliminate

03 Lingke Solution: Lace Machine Empowers Technological Breakthrough

Faced with many pain points of traditional craftsmanship, the customer chooses to establish a strategic partnership with Lingke Ultrasonic. Through in-depth technical integration and process validation, Lingke Ultrasonic has tailored an overall solution for ultrasonic lace machines for customers, achieving technological innovation in the core areas:

Welding process upgrade:

Using high-frequency ultrasonic bonding technology, material melting and bonding are achieved through molecular friction heat generation.

No pinhole sealing: The tooth pattern is beautiful and neat, there is no risk of needle hole leakage, and the sealing performance is improved by 50%

Efficient and energy-saving: Welding speed increased by 1.5 times, continuous welding without pause

Environmental Economy: No need for consumables such as sutures, reducing costs by about 30%

Material compatibility optimization:

Based on the characteristics of different materials, Lingke Ultrasonic summarizes the key points of welding process:

04 Industry Value

In this case, Lingke ultrasonic welding technology not only helped the customer achieve innovative breakthroughs in production processes, but also set a new benchmark for medical device welding quality. This successful practice provides a replicable technical template for the industry to solve the welding difficulties of high demand medical materials, and has important reference value.

With the continuous upgrading of product reliability and production efficiency requirements in the medical industry, Lingke Ultrasonic will always adhere to the concept of technological innovation and deeply cultivate the field of precision welding. By providing customized solutions and continuous technological iteration, we empower medical device companies to improve quality and efficiency, and jointly promote the industry towards safer and smarter development.