-

Contact Us

- Phone:13926939747

- Fax:+86 756 8679535

- Email:2850298518@qq.com

- Addr:NO.3 Pingxi Wu Road, Nanping Technology Park, Zhuhai City, Xiangzhou District, Guangdong Province, China

Jiangmen Taishan Ultrasonic Lace Machine

Auther: Date:2025/7/15

In Jiangmen Taishan, where industries such as textiles, healthcare, and packaging are flourishing, traditional sewing techniques are causing efficiency bottlenecks, pinhole water seepage, and loose thread ends, which are becoming pain points restricting the improvement of enterprise competitiveness. Faced with increasingly fierce market competition and rising labor costs, Taishan enterprises urgently need a more efficient, reliable, and environmentally friendly processing solution - the ultrasonic lace machine has emerged!

Why is ultrasonic lace machine the wise choice for Taishan enterprises?

Subverting tradition, efficient and energy-saving:Say goodbye to the constraints of needle and thread: The ultrasonic lace machine in Taishan, Jiangmen City uses high-frequency ultrasonic vibration to instantly fuse materials, completely eliminating the troubles of frequent needle and thread replacement, wire breakage and downtime, and significantly shortening the delivery cycle of orders.

High speed continuous operation: With strong processing capabilities, it can easily meet the needs of large-scale production and is a powerful assistant for Taishan enterprises to undertake large-scale orders and improve production capacity.

One machine with multiple functions, cost reduction:

Jiangmen Taishan Ultrasonic Lace Machine Integrated Operation: Multiple processes such as stitching, cutting, embossing, etc. are completed in one go! Significantly reduce equipment investment and process flow, lower manual dependence and error rates.Worry free process upgrade: Convenient installation of colored paper or gold foil can achieve high-quality printing, hot stamping and other effects, helping Taishan enterprises enhance product added value and market competitiveness.

Green and environmentally friendly, safe and comfortable:

Clean production: The ultrasonic lace machining process in Taishan City, Jiangmen is smoke-free, spark free, and does not require any chemical adhesives. It fully complies with international environmental standards and increasingly strict domestic environmental requirements, helping Taishan enterprises build green factories.Silent operation: The low-noise design significantly improves the working environment in the workshop, reflecting the company's care for employees.

The material is versatile and widely used:

Strong compatibility: Perfectly handling various thermoplastic materials such as non-woven fabrics, synthetic fabrics, PVC, TPU, etc., providing strong support for Taishan's diversified industrial foundation.Industry wide coverage: from medical protection to clothing, shoes, and hats, from household items to packaging and decoration, ultrasonic lace machines can show off their skills.

Easy to use, flexible and efficient:

Low operational threshold: Ordinary workers can quickly get started with simple training, effectively alleviating the pressure of "difficult employment and expensive training" for Taishan enterprises.

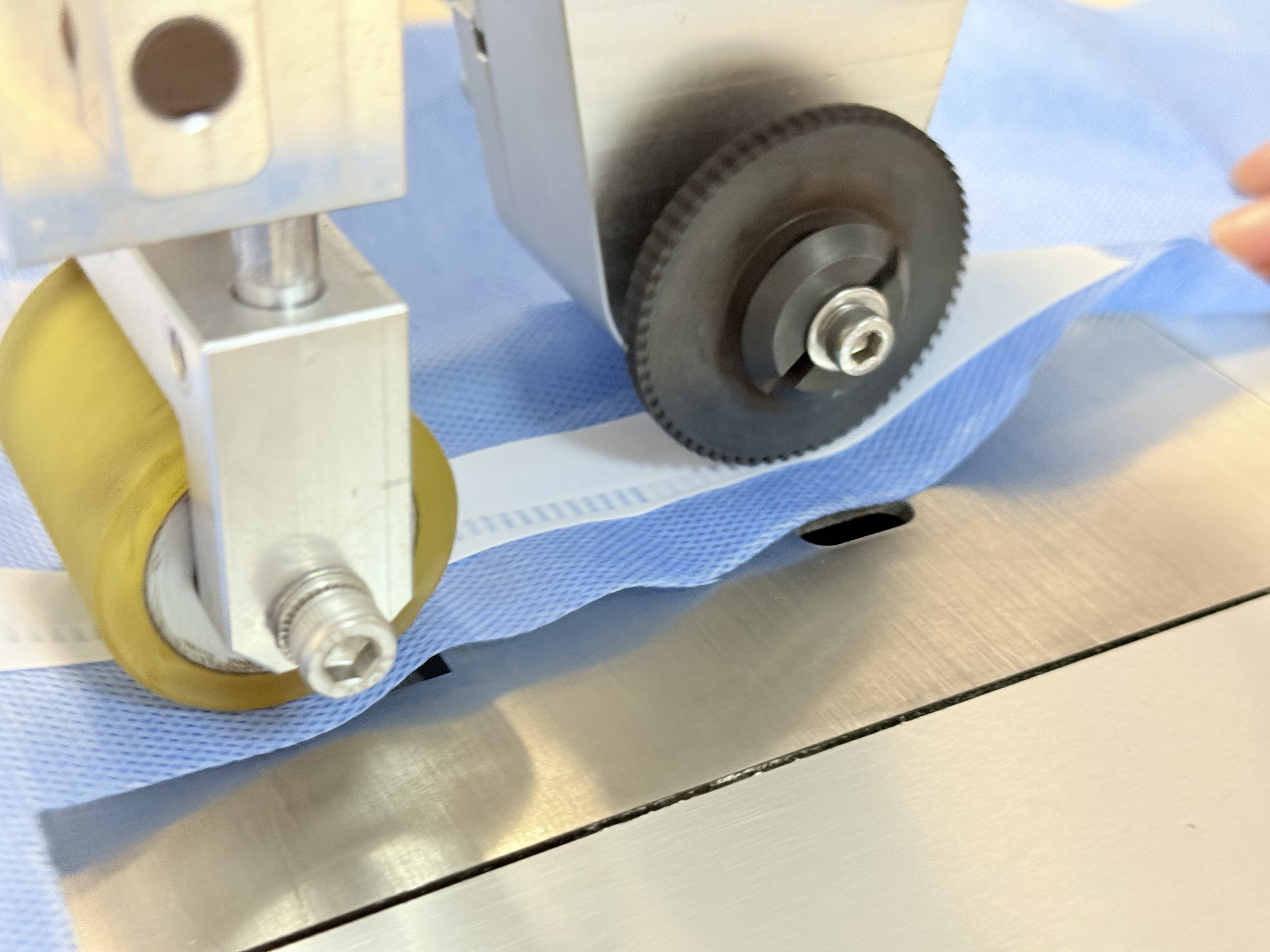

Flower wheel quick change: Different patterns require quick switching to meet the flexible production needs of small batches and multiple varieties, helping enterprises quickly respond to market changes.

The practical application value of ultrasonic lace machine in Taishan

Medical protection industry:

Welding of medical protective clothing/mask ear straps: achieving perfect sealing without pinholes, completely eliminating the risk of liquid penetration, and providing a truly reliable barrier for medical staff.

Surgical cap/shoe cover: The edges are melted and cut smoothly without burrs, enhancing wearing comfort and professional image.

Textile and clothing industry:

Underwear/swimsuit: achieve seamless edging, soft and snug edges, avoid skin friction, and enhance the wearing experience.

Sports clothing/outdoor equipment: Waterproof adhesive strips are welded firmly and durable, greatly improving the performance of the product in harsh environments.

Packaging and Decoration Industry:

Environmentally friendly non-woven bag: The handle fusion joint is exceptionally firm, significantly improving the load-bearing capacity and service life, showcasing brand quality.

Festival decorations: Cutting, embossing, and molding are all done in one step, greatly reducing labor costs and improving product aesthetics and consistency.

Based in Taishan, serving the world - choose Sonicpower to open a new chapter in intelligent manufacturing!

Faced with the wave of industrial upgrading, Taishan enterprises need trustworthy partners and leading equipment. Sonicpower has been deeply involved in the industry for 32 years and is your expert in ultrasonic welding technology! We not only provide high-performance, stable and reliable ultrasonic lace machines, but also have a deeper understanding of the pain points of manufacturing needs in Taishan and surrounding areas.

By selecting Sonicpower, you will receive:

Tailored: Provide optimal equipment selection and solutions based on your specific material, process, and production capacity requirements.

Efficient and reliable: The core components of the equipment are made of imported high-quality components, ensuring long-term continuous and stable operation, and safeguarding your production.

Localized services: We have established a comprehensive service network in the Pearl River Delta region, providing fast installation, debugging, training, and after-sales response to solve your worries.

Continuous empowerment: Provide professional technical support and process development advice to help you continuously tap into the potential of equipment and expand application areas.

Let Sonicpower ultrasonic lace machine become your "secret weapon" to improve quality, increase efficiency, reduce costs and protect the environment! Contact us immediately for free sample making and professional consultation, and work together to create a better future for Taishan Manufacturing!