Causes and solutions of unsound ultrasonic welding

Auther: Date:2020/11/20

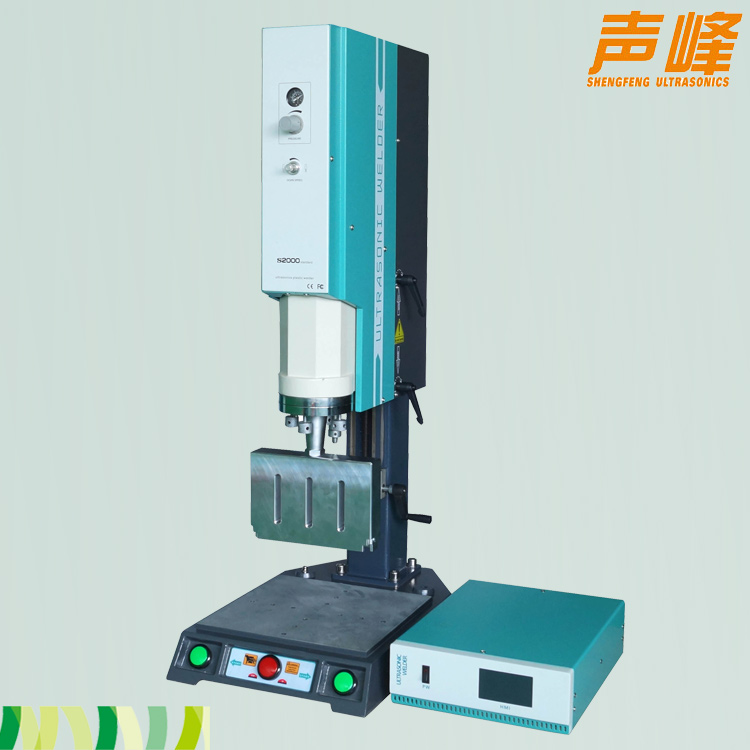

Causes and solutions of unsound welding of ultrasonic plastic welding machine

Causes and solutions of unsound welding of ultrasonic plastic welding machine

The first reason is that the frame is not precise enough

The ultrasonic welding machine seems to be an equipment with no difficulty except for the ultrasonic system. In fact, this is a wrong cognition. Although the ultrasonic electric box (generator) is the core part of the ultrasonic welding machine, in addition to the electric box part, there is the problem of the welding machine frame. If the frame design is unreasonable and the processing is not precise enough, it is likely to be straight in the use process The welding effect of your product is affected. If the machine design is unreasonable, the welding fastness of the product will be affected if the machine is tilted backward. The production of the frame is not precise enough, and it is difficult to adjust the balance position of the grinding tool when adjusting the mold, so it may also lead to the welding product not being welded.

resolvent:

1. Replace the precision rack, try to do a good job in the purchase of the machine, to understand the relevant information of the equipment.

2. Optional square column frame can prevent the machine from tilting backward.

The second reason is that the power of ultrasonic electric box is not enough

The power of ultrasonic electric box is not enough, which is also a factor leading to weak welding. When many factories purchase machines, they don't know the properties of the machine. They only see the appearance and price of the products. They will choose cheap machines, and often ignore the effect of post-processing. If the ultrasonic power is not enough and exceeds or approaches the maximum value of the welding range, it will also lead to weak welding 。

Solution: try to buy plastic welding machine suitable for your own use.

The third reason is the material problem of plastic parts

Now many plastic materials are added to other materials, which will also affect the welding fastness. In order to meet the requirements of product hardness, fire resistance and other properties, other materials are added to the raw materials in the process. If glass fiber is added to PC, it will affect the firmness of the whole welding.

resolvent:

1. A single thermoplastic material is used.

2. Increase vibration duration or pressure.

3. It is suggested to add welding line to welding surface

4. It is suggested to carve rolling pattern on the surface of welding head

5. It is suggested that the welding surface should be made of shear plane

Four reasons for instability of air pressure

Many factory workshops, working hours, multiple equipment colleagues use, will lead to the phenomenon of air pressure instability, resulting in the welding process in the actual air pressure and other work in a certain gap.

resolvent:

1. Working in different periods

2. Add an independent air compressor to supply air for ultrasonic plastic welding machine

More welding technical problems, you can consult the website customer QQ