-

Contact Us

- Phone:+86 756 8874271

- Fax:+86 756 8679535

- Email:2850298518@qq.com

- Addr:NO.3 Pingxi Wu Road, Nanping Technology Park, Zhuhai City, Xiangzhou District, Guangdong Province, China

Recommendation of high cost performance ultrasonic plastic welding machine

Auther:sonicpower Date:2020/11/19

At present, there are many ultrasonic plastic welding machine products on the market, but which one is cost-effective? Below, small make up for you to introduce a high-quality ultrasonic plastic welding machine products.

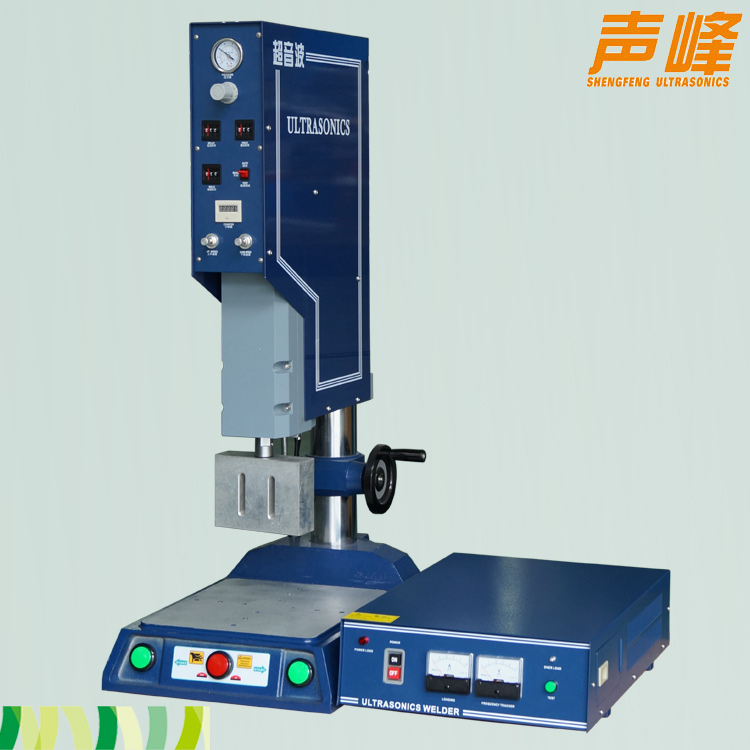

Product pictures.

Ultrasonic plastic welding machine is widely used in various industries, such as ultrasonic riveting, ultrasonic butt welding, ultrasonic punching, ultrasonic puncture and so on. It is suitable for the fusion processing of thermoplastic rubber parts in toys, household appliances, electronics, automobiles and other industries.

Brand new and improved, new design of ultrasonic electric box

The new ultrasonic electric box designed in this device has beautiful and solid structure, small volume, light and simple, easy to install on the body, and does not need to occupy too much space. The ultrasonic electric box is flexibly adjusted in various directions, which is suitable for operators of different shapes for production. It conforms to ergonomics. The heat dissipation fan of the electric box is equipped with dust screen, fan and filter cotton to ensure the flow into the electric box The air is clean.

High welding efficiency, more convenient operation

Ultrasonic plastic welding machine can replace the traditional industry of glue bonding. In the process of ultrasonic welding, there are no bolts, nails, clasps, welding materials or adhesives. It is faster than the traditional adhesive or glue, and the drying time is also very fast. The welding process can be easily realized automatically, and can be easily customized to adapt to various types of Products of specific specifications are welded. The machine has the advantages of high welding strength, fast production efficiency and environmental protection.

Quality assurance, better performance

The ultrasonic plastic welding machine adopts frequency modulation and frequency automatic compensation circuit, Japanese original piezoelectric ceramic transducer, with strong and stable output; debugging and setting up soft start circuit to avoid damage to the mold; CNC machine tool processing of important components, high precision; complete set of high-quality parts and components, quality assurance.

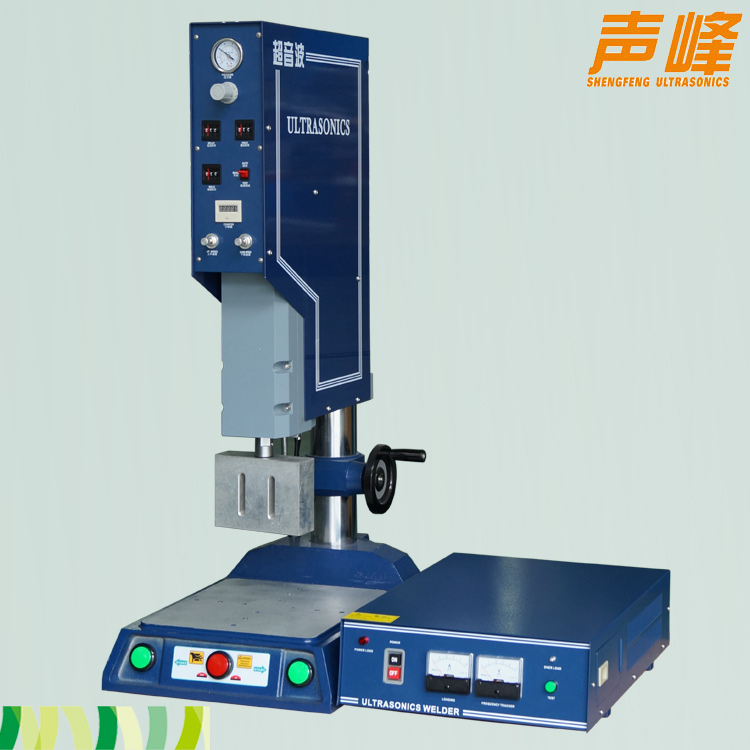

Product pictures.

Ultrasonic plastic welding machine is widely used in various industries, such as ultrasonic riveting, ultrasonic butt welding, ultrasonic punching, ultrasonic puncture and so on. It is suitable for the fusion processing of thermoplastic rubber parts in toys, household appliances, electronics, automobiles and other industries.

Brand new and improved, new design of ultrasonic electric box

The new ultrasonic electric box designed in this device has beautiful and solid structure, small volume, light and simple, easy to install on the body, and does not need to occupy too much space. The ultrasonic electric box is flexibly adjusted in various directions, which is suitable for operators of different shapes for production. It conforms to ergonomics. The heat dissipation fan of the electric box is equipped with dust screen, fan and filter cotton to ensure the flow into the electric box The air is clean.

High welding efficiency, more convenient operation

Ultrasonic plastic welding machine can replace the traditional industry of glue bonding. In the process of ultrasonic welding, there are no bolts, nails, clasps, welding materials or adhesives. It is faster than the traditional adhesive or glue, and the drying time is also very fast. The welding process can be easily realized automatically, and can be easily customized to adapt to various types of Products of specific specifications are welded. The machine has the advantages of high welding strength, fast production efficiency and environmental protection.

Quality assurance, better performance

The ultrasonic plastic welding machine adopts frequency modulation and frequency automatic compensation circuit, Japanese original piezoelectric ceramic transducer, with strong and stable output; debugging and setting up soft start circuit to avoid damage to the mold; CNC machine tool processing of important components, high precision; complete set of high-quality parts and components, quality assurance.